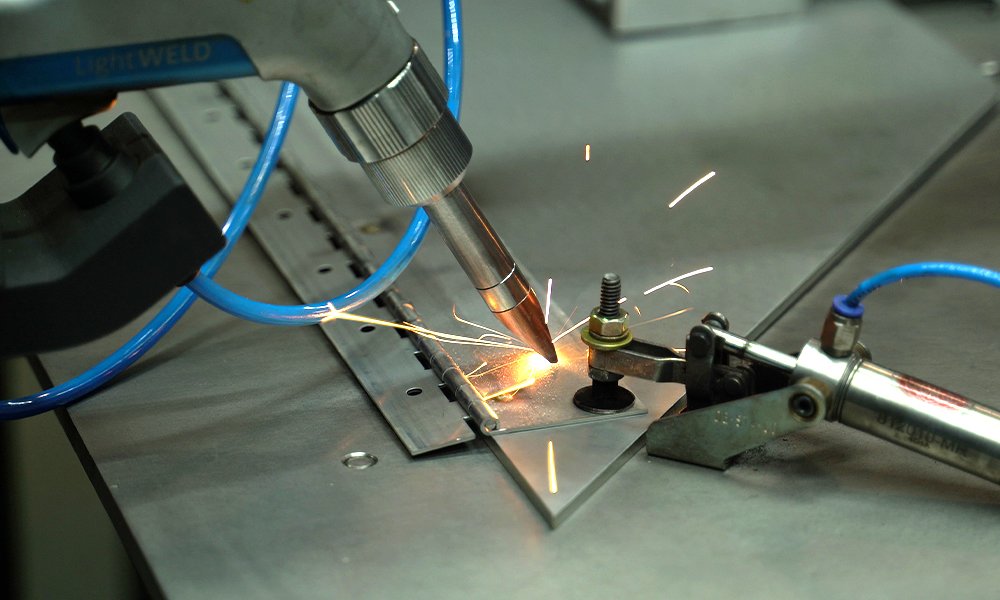

In modern manufacturing, precision, speed, and reliability are crucial. Whether you’re in automotive production, metal fabrication, or custom manufacturing, a laser welding machine can elevate your operational efficiency and product quality. However, the success of your investment depends largely on selecting the right laser welding machine supplier.

Choosing the wrong supplier can result in poor machine performance, inconsistent welds, limited after-sales support, and unnecessary downtime. These issues not only disrupt production but can also lead to higher long-term costs and reduced customer satisfaction.

This guide explains how to evaluate potential suppliers, what key factors to consider, and how to ensure you make a well-informed decision. By understanding what truly defines a reliable supplier, you’ll be better equipped to secure long-term performance and value from your investment.

Understanding Your Welding Requirements

Before comparing suppliers, assess your specific needs to find the best match. Focus on the following key factors:

- Material and Thickness: Identify the materials you weld most often—stainless steel, carbon steel, aluminum—and their thickness to determine the required laser power and settings.

- Production Scale: Match the machine to your workload. Custom workshops need flexible units, while large factories require high-capacity systems.

- Automation Level: Decide whether you need a handheld, semi-automatic, or fully automated system.

- Operator Skill and Training: Ensure the equipment suits your team’s skill level and that training support is available.

- Workspace Conditions: Check your facility’s space, ventilation, and power capacity for machine compatibility.

Defining these factors helps you focus on suppliers who can deliver the most efficient and reliable solution for your operations.

Evaluating Supplier Experience and Reputation

A supplier’s experience and reputation are strong indicators of reliability. When reviewing potential partners, focus on the following:

- Industry Experience: Choose suppliers with several years of proven expertise in laser welding technology.

- Certifications and Standards: Look for ISO, CE, or similar quality and safety certifications.

- Track Record: Ask for case studies or client references, especially from businesses similar to yours.

- Customer Feedback: Check online reviews, forums, and testimonials for insights on service quality and responsiveness.

- Transparency: Reliable suppliers provide detailed technical data, testing reports, and are open to demonstrations or product trials.

Selecting an experienced and reputable supplier ensures consistent machine quality, dependable service, and long-term support.

Assessing Product Quality and Technical Capabilities

Not all laser welding machines are created equal. Before making a purchase, take a close look at the supplier’s product range and technical specifications. Reliable suppliers should be able to provide machines that balance power, precision, and ease of use.

Here are some important factors to evaluate:

- Laser Power Output: Determines how deep and fast the machine can weld.

- Beam Quality: Influences welding precision and the appearance of the finished joint.

- Cooling System: Prevents overheating during long production runs.

- Control Software and Interface: A user-friendly interface allows easier setup and operation, minimizing errors.

- Machine Durability: High-quality components ensure longer operational life and fewer maintenance issues.

Ask suppliers to provide sample welds or arrange demonstrations. Observing the equipment in action gives insight into the consistency of welds, energy efficiency, and stability under continuous operation.

It’s also important to ensure that machines comply with international safety and quality standards. A supplier that prioritizes compliance typically maintains rigorous internal quality control systems, ensuring better performance and reliability.

After-Sales Support and Service Commitment

A truly reliable supplier’s responsibility doesn’t end after delivery. Comprehensive after-sales service is essential to maximize uptime and maintain long-term productivity.

When evaluating a supplier’s support structure, consider the following:

- Warranty Terms: Understand what is covered, including labor, spare parts, and service visits.

- Technical Support: Ensure the supplier offers quick response times and multiple support channels (phone, email, remote diagnostics).

- Spare Parts Availability: Check whether parts are readily available and how quickly they can be shipped.

- Training Programs: A good supplier will offer operator and maintenance training—either on-site or online—to help your team use the machine effectively.

Reliable after-sales service can significantly reduce downtime and extend the lifespan of your laser welding system. It also reflects the supplier’s confidence in the quality and durability of their products.

Comparing Pricing and Long-Term Value

While price is often a deciding factor, it should never be the only one. The lowest initial cost does not always represent the best value over time. Instead, focus on the total cost of ownership—including maintenance, energy efficiency, spare parts, and operator training.

Consider these key metrics when comparing suppliers:

- Operational Costs: How much power and gas the machine consumes.

- Maintenance Costs: Frequency and cost of servicing and part replacements.

- Machine Longevity: Expected lifespan under normal production conditions.

- Return on Investment (ROI): The timeframe in which the machine’s productivity offsets its purchase cost.

Suppliers that prioritize long-term efficiency and reliability often deliver better ROI, even if their machines come at a slightly higher initial price. It’s worth calculating the cost difference between short-term savings and long-term performance.

Read Also: The Benefits of Using a 5G Router for Faster and More Reliable Internet Connection

Innovation and Technological Advancement

Laser welding technology continues to evolve rapidly. Working with a supplier that embraces innovation ensures your operations stay competitive and adaptable.

Look for suppliers that actively invest in research and development (R&D). These companies typically offer advanced features such as:

- Real-time monitoring and adaptive control systems

- AI-based welding parameter adjustments

- Ergonomic designs for improved operator comfort

- Enhanced safety mechanisms and automatic shutdown systems

A supplier’s commitment to innovation reflects their long-term vision. Choosing a partner that continually upgrades its technology helps your business maintain efficiency and reduce the risk of obsolescence.

Communication, Transparency, and Reliability

Effective communication is a hallmark of a dependable supplier. From the first inquiry to final delivery, transparency builds trust and ensures smoother collaboration.

Pay attention to how promptly and clearly a supplier responds to your questions. A reliable company provides detailed quotations with full specifications, transparent pricing, and clear timelines. They should also be upfront about delivery schedules, warranty terms, and potential limitations.

Denaliweld exemplifies this approach by maintaining open communication and clear project coordination from consultation to after-sales support. Their commitment to responsiveness and honesty ensures that clients receive accurate information and dependable service at every stage.

Building a Long-Term Partnership

Selecting a laser welding machine supplier is more than a simple transaction—it’s the foundation for a long-term partnership. The right supplier can grow with your business, offering ongoing support, upgrades, and training as your production needs evolve.

Look for companies that are financially stable, responsive to feedback, and committed to continuous improvement. They should see your success as part of their own. A long-term relationship fosters smoother collaboration, better technical alignment, and mutual trust—key ingredients for sustained productivity and innovation.

Conclusion

Choosing a reliable laser welding machine supplier is one of the most important decisions for any manufacturing or fabrication business. By taking the time to understand your welding requirements, verifying experience and certifications, assessing product quality, and prioritizing after-sales service, you set the stage for long-term operational success.

The ideal supplier offers more than just a machine—they provide a complete support system that ensures performance, safety, and efficiency. When you select a partner who values quality, transparency, and innovation, you gain not just equipment, but confidence in every weld your business produces.

Investing in the right supplier is investing in the future of your production. With informed decisions, you’ll enjoy smoother operations, higher productivity, and lasting value for years to come.

You May Also Like: How to Choose the Right Size Water Heater for Your Home