Achieving a strong and durable bond between materials hinges significantly on proper surface preparation. Without attention to the condition of the bonding surfaces, even the most advanced adhesives may fail to deliver their full performance. Knowing how to prepare a surface correctly can dramatically enhance the longevity and strength of any adhesive application. Explore comprehensive techniques and product solutions at https://leechadhesives.com/ for professional-grade bonding results.

Surface contaminants, inconsistent textures, and low-energy materials are common hurdles in both industrial and residential bonding projects. Identifying and mitigating these obstacles before adhesive application is critical for reliable, long-lasting performance.

For challenging projects, ranging from plastics to metals, proven preparation methods include simple cleaning to advanced activation processes. Understanding which technique—or combination of techniques—to use for a given substrate is key to maximizing adhesive effectiveness and ensuring your project stands the test of time.

Understanding Surface Contaminants

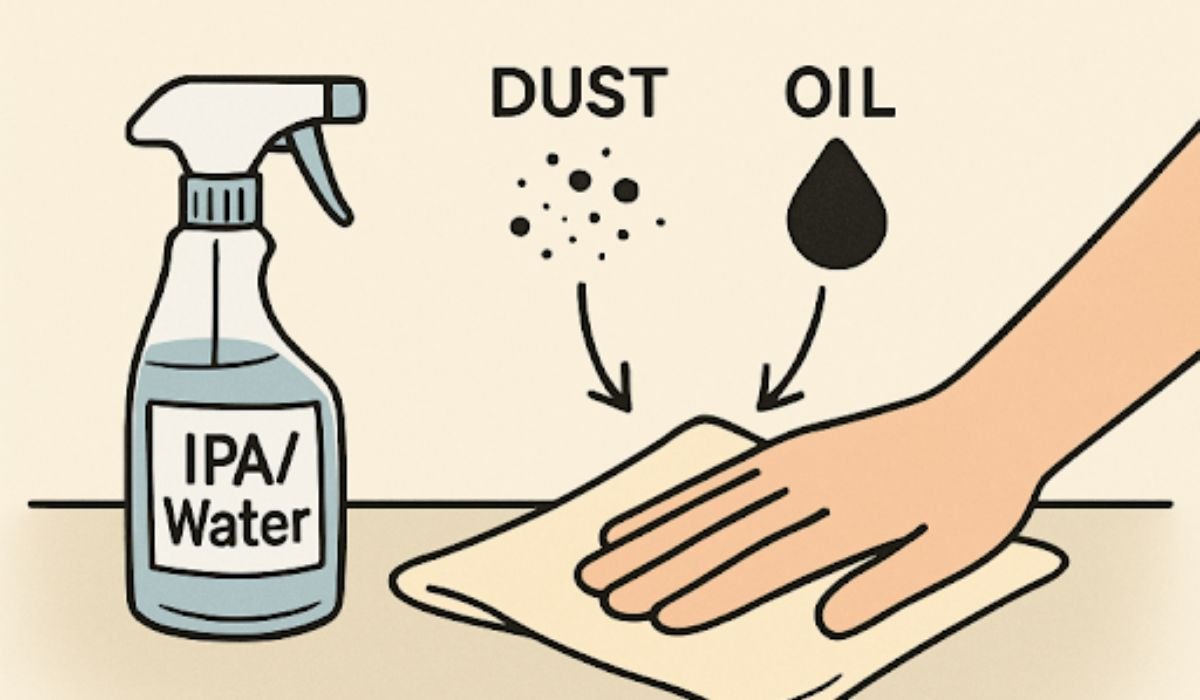

Thorough cleaning is the foundation of successful surface preparation. Contaminants like dust, oils, grease, and even subtle residues from previous processes inhibit an adhesive’s ability to form a reliable bond. A cost-effective and widely recommended method is to clean surfaces with a 50:50 mixture of isopropyl alcohol (IPA) and water. This solution is effective for dissolving light oils, removing loose debris, and evaporates without leaving harmful residues. For more robust contaminants, specialized degreasers may be necessary, always followed by a rinse and drying step to ensure the surface is spotless before further treatment.

Mechanical Abrasion: Enhancing Surface Area

On especially smooth or non-porous surfaces, improved mechanical adhesion is achieved by lightly roughening the material. Sandblasting and sanding—using fine-grit sandpaper (220 to 400 grit)—are both practical solutions. Sandblasting is particularly effective for ferrous and non-ferrous metals as well as rigid plastics, creating a microscopically textured surface for the adhesive to grip. After sanding or blasting, always conduct a cleaning step to remove generated particulate, as leftover dust can undermine the adhesive interface. Resources from Popular Mechanics offer additional sandpaper selection and safety tips.

- Sandblasting: Enhances roughness and is ideal for industrial metals and large-scale applications.

- Sanding: More controlled for small areas or delicate substrates—ensure even pressure to avoid gouges.

Mechanical abrasion not only provides a better anchor for adhesives but also removes potential surface oxides and aged layers that might interfere with bonding.

Chemical Treatments: Altering Surface Chemistry

Certain materials benefit from chemical intervention to enhance adhesion. Two widely used techniques are etching and priming:

- Etching: This treatment involves applying a mild acid or alkali to remove the natural oxide or inert layer, particularly on metals such as aluminum. Sulfuric acid etching, for example, is shown to improve the adhesive bond on aluminum alloys by creating a more chemically active surface.

- Priming: Adhesive primers contain reactive molecules that chemically bond to both the substrate and the adhesive, significantly enhancing adhesion, especially with difficult-to-bond plastics like polypropylene and polyethylene.

The choice of chemical must align with the base material to avoid undesired reactions or substrate degradation. Safety precautions, including the use of gloves and proper ventilation, are always non-negotiable during chemical preparation steps.

Advanced Surface Activation Techniques

Low-surface-energy substrates, such as polyethylene, polypropylene, and certain fluoropolymers, pose special challenges for adhesives. Advanced activation methods like plasma and flame treatments are employed to increase surface reactivity:

- Plasma Activation: By exposing the material to a low-temperature plasma, functional groups are introduced, making the surface more chemically attractive to adhesives.

- Flame Treatment: Passing the material through a controlled flame similarly alters its surface energy and improves bonding capability. These methods are especially vital in automotive, packaging, and electronics applications where robust bonds are required on plastics.

Combining Techniques for Optimal Results

Optimal adhesive strength is typically achieved by combining various surface preparation methods. For example, mechanically double-roughening a surface followed by a chemical primer can significantly enhance the integrity and performance of the bond. Multi-step procedures are frequently used in high-stress applications such as aerospace and automotive manufacturing, where failure is not an option. A study on reinforced composites found that pairing abrasion with nanoparticles in adhesive layers enhanced both load-bearing capacity and fracture resistance, underscoring the value of a tailored, multifaceted preparation strategy.

Practical Considerations and Best Practices

- Material Compatibility: Tailor your surface preparation method to the material. For example, metals may benefit more from sandblasting, while plastics may require primers or plasma treatment.

- Environmental Factors: Temperature, humidity, and chemical exposures during curing can impact the adhesive’s performance. Always review adhesive manufacturer guidelines for application parameters.

- Safety Measures: Proper ventilation, the use of appropriate personal protective equipment (PPE), and adherence to chemical safety protocols are crucial, especially when working with abrasives or strong solvents.

These considerations are critical not only to maximizing adhesive strength but also to ensuring the long-term reliability and safety of the bonded assembly.

Final Thoughts

Successful adhesive applications are built upon methodical and material-specific surface preparation. From simple degreasing to complex activation treatments, each step serves to enhance interface contact and create conditions for a durable, high-strength bond. By systematically assessing the requirements of each project and selecting the appropriate preparation techniques, both do-it-yourselfers and professionals can achieve reliable, lasting adhesive results that meet or exceed performance expectations.

YOU MAY ALSO LIKE: The Impact of Dirt and Debris on Velcro