Ever felt like you’re only seeing half the picture? Like there’s a whole world of detail hidden just beneath the surface, whether it’s in a critical machine part, a security checkpoint, or even within your own health? What if you had a tool that could peel back those layers, revealing insights so profound they change the game entirely? That’s the promise, and increasingly, the reality, of Omega Scan.

Forget clunky, slow, or limited scanning methods of the past. Omega Scan technology represents a leap forward, offering unprecedented clarity, depth, and speed. It’s not just about seeing more; it’s about understanding better. Whether you’re an engineer safeguarding infrastructure, a security professional protecting assets, or a healthcare provider seeking deeper diagnostics, Omega Scan is emerging as a transformative force. Let’s dive into what makes it so revolutionary.

What Exactly is Omega Scan? (It’s More Than Just a Fancy X-Ray)

Think of Omega Scan as a super-powered flashlight for the invisible. While traditional scans capture surface images or basic internal structures, Omega Scan leverages advanced sensor fusion, AI-driven analysis, and often multi-spectral imaging to build a comprehensive, multi-dimensional picture.

- Beyond Pixels: It captures data about composition, density, stress points, potential anomalies, and even predictive failure signatures that simpler scans miss.

- Depth Perception: It doesn’t just show what is there; it shows how it’s structured internally, layer by layer.

- Speed & Efficiency: Modern Omega Scan systems are often significantly faster than older technologies, enabling real-time analysis or rapid screening of large volumes.

Imagine inspecting an aircraft wing. A standard scan might show a crack. Omega Scan could reveal the microscopic stress patterns around that crack, predict its propagation path, and analyze the material fatigue in the surrounding area – all in one pass.

The Future is Now: Top 3 Ways Industries Are Using Omega Scan Today

This isn’t science fiction. Omega Scan is actively reshaping industries:

- Revolutionizing Security & Non-Destructive Testing (NDT):

- Airports & Critical Infrastructure: Moving beyond simple metal detection. Omega Scan systems can identify specific material compositions (e.g., differentiating plastics, liquids, explosives), detect concealed threats within complex objects, and analyze structural integrity without disassembly.

- Manufacturing & Engineering: Ensuring weld integrity, detecting hidden corrosion in pipelines or bridges, verifying composite material quality, and identifying voids or inclusions in critical components with incredible accuracy. Example: AeroDyn Solutions reported a 30% reduction in aircraft grounding time by using Omega Scan for predictive maintenance on landing gear components.

- Transforming Medical Diagnostics & Research:

- Early & Precise Detection: Offering deeper tissue analysis, identifying subtle physiological changes indicative of disease earlier than conventional methods. Think beyond structure to function and composition.

- Personalized Medicine: Providing detailed data for tailored treatment plans, monitoring treatment efficacy at a cellular level in some advanced applications.

- Example: Research hospitals like the Cleveland Clinic are pioneering Omega Scan techniques for detailed neurological mapping and early tumor characterization.

- Boosting Quality Control & Material Science:

- Pharmaceuticals: Verifying pill composition uniformity and detecting microscopic contaminants within sealed packaging.

- Electronics: Identifying tiny defects in circuit boards or semiconductor wafers invisible to optical inspection.

- Materials Development: Analyzing the internal structure of new alloys, composites, or biomaterials at an unprecedented scale.

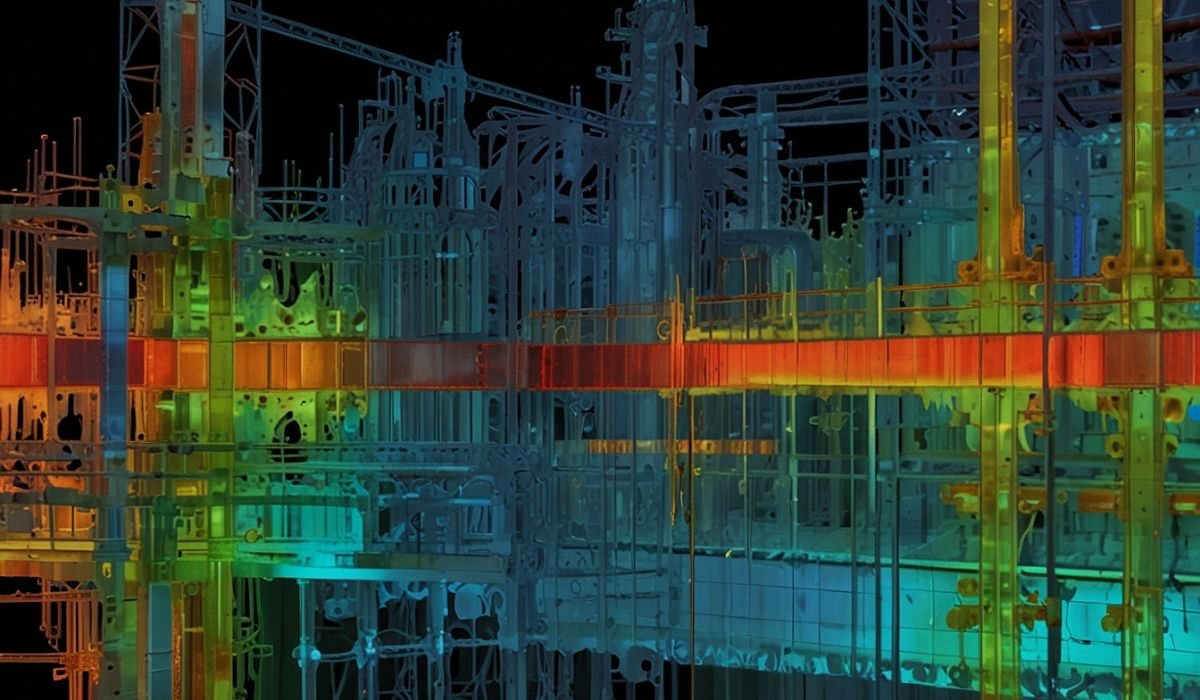

Visualizing the Advantage:

Imagine an infographic showing a traditional scan result (a blurry, flat image) side-by-side with an Omega Scan result (a vibrant, multi-layered 3D model highlighting density variations, stress points, and potential flaws). The difference in actionable information is stark.

Why Omega Scan Beats Traditional Methods (The Real Advantages)

Sure, it sounds cool, but what’s the tangible benefit? Here’s why organizations are making the switch:

- Unmatched Accuracy & Detail: See what others miss, reducing false positives and negatives.

- Predictive Power: Identify potential failures before they happen, enabling proactive maintenance and saving massive costs (and potentially lives).

- Speed & Throughput: Scan faster and handle larger volumes, improving efficiency and reducing bottlenecks (think security lines or production floors).

- Non-Invasive Insight: Get deep internal data without disassembly, destruction, or invasive procedures.

- Data-Rich Output: Generate comprehensive reports not just with images, but with actionable metrics and analysis.

Myth Busting: “Omega Scan must be prohibitively expensive and complex!” While advanced, costs are decreasing rapidly as technology matures. The ROI from preventing failures, improving efficiency, and enabling new discoveries often outweighs the investment significantly. User interfaces are also becoming more intuitive.

Getting Started with Omega Scan: What You Need to Know

Ready to explore if Omega Scan is right for your needs? Here’s a quick roadmap:

- Define Your Problem: What specific challenge are you trying to solve? (e.g., “Detect micro-cracks in turbine blades,” “Screen luggage faster for specific threats,” “Map blood flow dynamics in deep tissue”).

- Research Solutions: Look for Omega Scan providers specializing in your industry. Key specs to compare:

- Penetration Depth & Resolution: How deep and how detailed can it see?

- Scanning Speed: How long per scan/item?

- Data Output & Analysis: What kind of reports and insights does it generate? How is AI used?

- Integration: How easily does it fit into your existing workflow?

- Consider the Workflow: Factor in training needs, data storage/analysis requirements, and potential process changes.

- Pilot Program: If possible, start with a pilot project to validate the technology’s effectiveness for your specific use case.

Read also: Peñiculs: A Holistic Approach to Health and Wellness

Simple Comparison: Traditional Scan vs. Omega Scan

| Feature | Traditional Scan (e.g., Basic X-Ray, Metal Detector) | Omega Scan Technology |

| Detail Level | Surface/Basic Internal Structure | Multi-Layer, Compositional, Stress |

| Information | “Something is there” / “Density variation” | “What it is, its condition, potential risks” |

| Speed | Variable (Often Slower for detail) | Generally Faster & More Automated |

| Predictive | Limited/Reactive | High Potential for Proactive Insights |

| Data Output | Primarily Image | Image + Metrics + AI Analysis |

The Future Horizon: Where Omega Scan is Headed

The evolution of Omega Scan is incredibly exciting. We’re looking at:

- AI Integration Deep Dive: Moving beyond analysis to real-time, autonomous decision-making based on scan data.

- Miniaturization & Portability: Handheld or drone-mounted Omega Scan devices becoming commonplace for field use.

- Multi-Sensory Fusion: Combining scanning data with thermal, acoustic, or chemical sensors for even richer context.

- Biomedical Breakthroughs: Applications in real-time surgical guidance, ultra-early disease detection, and personalized treatment monitoring at unprecedented levels.

The bottom line? Omega Scan is moving us from simply observing to truly understanding the hidden world around and within us.

Your Omega Scan Action Plan: 3 Things to Consider Tomorrow

- Audit Your Needs: Where in your operations or field could deeper, faster, more predictive insights make a massive difference? Is it safety, quality, efficiency, or discovery?

- Explore the Landscape: Spend 30 minutes searching for “Omega Scan solutions for [Your Industry]”. See what’s out there and who the key players are.

- Ask the Right Question: Instead of “Can a scan detect X?”, start asking “Can a scan tell me the condition, composition, and future risk of X?”

Omega Scan isn’t just a tool; it’s a paradigm shift in perception. What hidden challenge could it help you solve?

FAQs

- Q: Is Omega Scan safe?

A: Safety depends entirely on the specific technology used (e.g., radiation levels in some X-ray based systems, laser safety in optical systems). Reputable providers adhere strictly to stringent safety regulations for their intended applications (medical, industrial, security). Always check the safety certifications for the specific system. - Q: How much does an Omega Scan system cost?

A: Costs vary widely based on the technology’s complexity, depth/resolution required, application (medical vs. industrial), and scale. They can range from tens of thousands for specialized portable units to millions for large, cutting-edge medical or security installations. The key is evaluating the ROI through improved outcomes, reduced downtime, or enhanced security. - Q: Can Omega Scan replace all other scanning methods?

A: Not necessarily. While incredibly powerful, Omega Scan might be overkill (or too expensive) for simple applications where basic scans suffice (e.g., checking for large metal objects). It excels where deeper analysis, material identification, or predictive insights are needed. It often complements existing technologies. - Q: How accurate is Omega Scan?

A: Advanced Omega Scan systems boast very high accuracy rates, significantly exceeding many traditional methods, especially in detecting subtle anomalies or characterizing materials. Accuracy is continually improving with better sensors and AI algorithms. However, no technology is infallible, and results should be interpreted by trained professionals. - Q: Do I need special training to use or interpret Omega Scan results?

A: Yes. While user interfaces are improving, operating complex Omega Scan equipment and, more importantly, accurately interpreting the rich, multi-layered data it produces requires specialized training. Providers typically offer comprehensive training programs. - Q: How fast is an Omega Scan?

A: Speed is a major advantage of many modern Omega Scan systems compared to older, detailed inspection methods. Scan times can range from milliseconds for simple security screening to minutes for highly complex, high-resolution 3D scans of large objects. It’s generally much faster than destructive testing or manual disassembly for inspection. - Q: Is the data from Omega Scan secure?

A: Data security is paramount, especially for sensitive applications like medical imaging or security screening. Reputable providers implement robust encryption, access controls, and comply with relevant data privacy regulations (like HIPAA in healthcare). Ensure you understand the provider’s data security protocols.

You may also like: Managing Stress and Fatigue During Pregnancy: A Complete Guide